INDUSTRIAL HYDRAULIC SEALS

Billets / Slabs

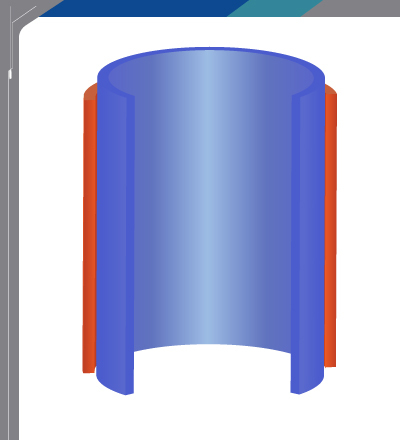

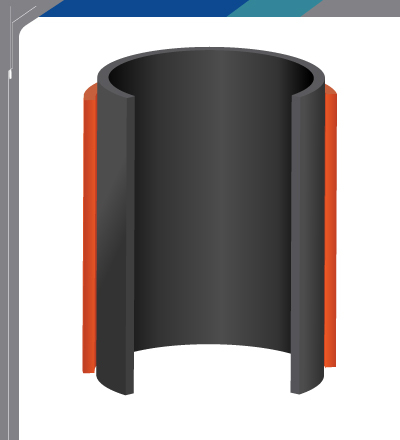

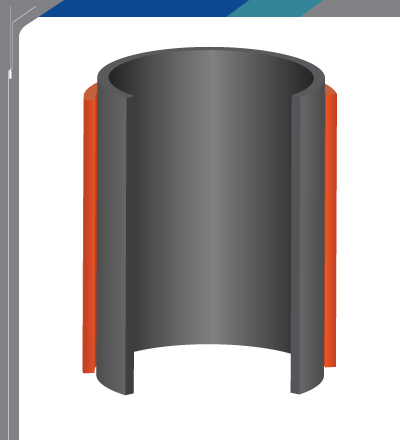

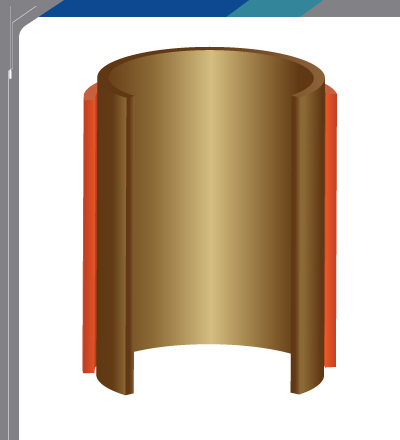

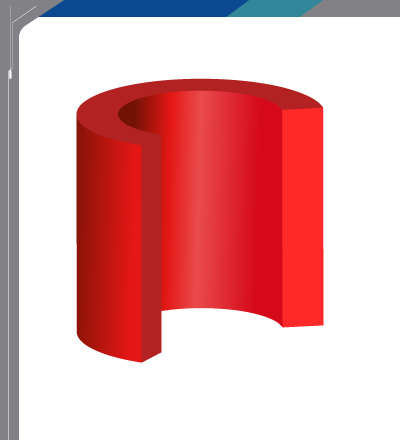

Nitrile Elastomer NBR hardness 85 (Nitrile Butadiene Rubber). Used for general applications and resistant to mineral oils, HFC, and cold water. Can be used to manufacture hydraulic rod and piston seals, wipers, radial and static seals. The material comes with a small orange resin coating which is removed during CNC machining. The purpose of this coating is to increase material firmness during machining and prevent deformation during storage. Download Technical Sheet

This is an EPDM material (Ethylene-Propylene-Diene Rubber) hardness 88. Also presented with orange resin coating. Resistant to HFC, cold and hot water, and diluted acids. Commonly used in applications exposed to environmental ozone. Suitable for hydraulic rod and piston seals, wipers, radial and static seals. Download Technical Sheet

FKM or FPM material (Fluorocarbon Elastomer) hardness 80. Also presented with orange resin coating. Commonly used in applications that involve contact with acids and chemicals at high temperatures. Suitable for hydraulic rod and piston seals, wipers, radial and static seals. Lower cost than brown FKM. Download Technical Sheet

FKM or FPM material (Fluorocarbon Elastomer) hardness 85. Also presented with orange resin coating. Commonly used in applications that involve contact with acids and chemicals at high temperatures. Suitable for hydraulic rod and piston seals, wipers, radial and static seals. Download Technical Sheet

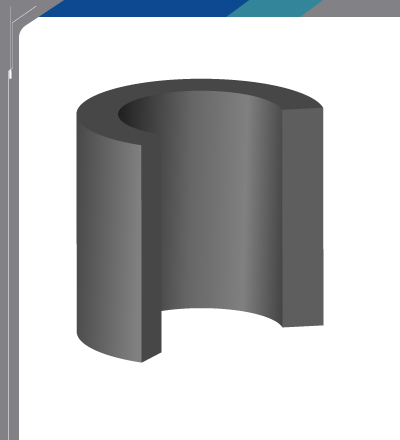

H-PU Slab (Hydrolysis Resistant Polyurethane) hardness 95. A thermoplastic with the "H" characteristic allowing use in water applications. Due to its hardness, it does not have an orange resin coating. Resistant to mineral oils, cold water, HFD-U, HETG, bio-based fluids, acidic oils, gases, and diluted acids with water. Suitable for hydraulic rod and piston seals, wipers, static and radial seals, backings, and wear guides. Download Technical Sheet

White thermoplastic called POM (Copolymer based on methylenoxide), commercially known as Delrin®. This material is used, among other applications, for wear guides in composite seals. Very hard material, not coated. Resistant to mineral oils, HFC, HFD-U, HETG, cold water, and diluted acids. Download Technical Sheet

Virgin PTFE (Polytetrafluoroethylene) is a tetrafluoroethylene fluoropolymer with numerous applications. Being virgin, it has no added materials. Known as PTFE, developed by DuPont Co. Broad chemical and temperature resistance. Very low friction coefficient, inert, non-contaminating, and excellent machinability. Download Technical Sheet